Coating equipment is an important key to the coating pr […]

Coating equipment is an important key to the coating production line, and its quality and maintenance must be adequate. If it is advanced coating equipment, but improper operation management and maintenance, it will still become an obstacle to the coating production line. Maintaining a good technical state of the coating equipment is one of the necessary conditions to ensure the coating sequence and coating quality.

If the technical condition of the coating equipment is not good and timely and regular maintenance is not done, it will not only seriously affect the performance of the equipment, but also cause damage to the coating equipment and cause unpredictable losses. Especially for the operation of painting equipment, management is more important, such as conveyor chain pumps and fans. General machine operation needs lubrication, high-temperature equipment needs cooling, etc. These all need to be checked and preserved during production. Once the measurement is insufficient, the equipment is extremely prone to problems.

In paint production lines with clean air supply systems, dust problems are prone to occur. It's good to start with new equipment. After a period of production, there will be more or less dust particles on the coating of the workpiece. The reason is that the purification filter is already covered with dust and has not been cleaned up in time. Especially in an environment where production equipment is often exposed to a lot of dust, it is necessary to clean the filter system frequently, otherwise it will cause the purifier to block.

Coating means that the product is processed into metal, plastic, wood and other materials, and the surface is covered with a protective layer or a decorative layer. With the development of industrial technology, the development of coating technology and equipment in China has become manual. The development process and coating process from mechanical equipment to automated production line are generally: pre-treatment, polishing, coating, leveling, drying, or solidification three-slag treatment. Coating equipment is the mechanical equipment used to complete these coating processes.

Therefore, poorly maintained coating equipment not only cannot guarantee the quality of coating, but also increases repair costs and scrap rate of finished products, affecting production plans and increasing production costs. The worse the team management, the more problems. When the production team encounters more problems, you should pay attention to the gap in team management. Manage the coating equipment, otherwise it will greatly increase unnecessary costs.

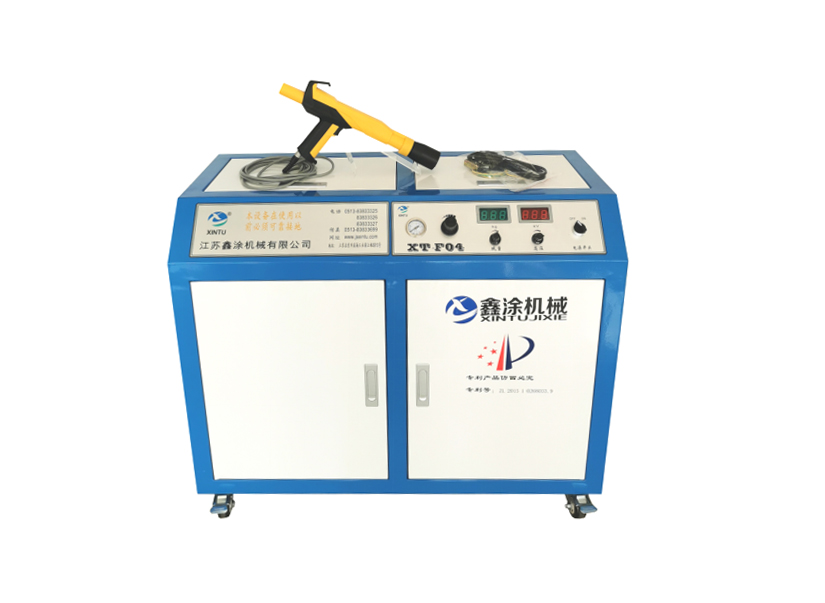

Found in 2006, Hangzhou Guozhen WanXin Coating Equipment Manufacturing Co.,Ltd is a professional China Powder Coating Equipments Manufacturers and Powder Coating Equipmens accessories dactory, our company that integrates R & D, production and sales, specializing in the manufacturing of powder coating equipment and flocking machines , our company found in 2006, located in Hangzhou city, and the production base in Jiangsu province, our factory covers an area of about 24,000 square meters , we has advanced production equipment, supporting facilities and a complete range of testing instruments.Powder coating equipment including: powder coating machines, Automatic powder coating systems, Powder coater, Powder Coating booth ,Cyclone type powder coating recovery system,Ovens, powder coating production line and various spare parts for different brand powder guns. Flocking equipment including: Printing flocking machine, Box-type flocking machine, portable flocking machine, Spray gun type Flocking machine and Automatic flocking lines and so on. WANXIN products are in line with international standards and have passed a number of quality certifications, such as CE, SGS , ATEX, ISO9001, Welcome!